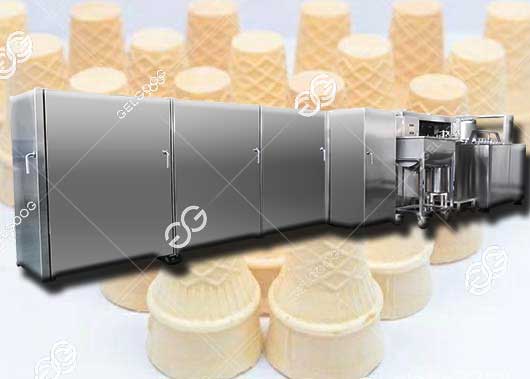

Efficiency Wafer Cone Line Solution

Efficient Wafer Cone Production Line High Power Industrial

The waffle cone production line is mainly composed of batter mixer, baking forming machine, conveyor belt, metal detector, wafer cone arrangement machine, air compressor and other components. It is specially used for large-scale production of waffle cones, waffle cups and other products. It can realize the full process automation from batter preparation, injection, baking, cooling to packaging.

Wafer Cone Production Line

Fully Automatic Wafer Cone Production Line Details

- Injection system: The injection head moves synchronously with the baking mold, and can quantitatively inject the batter into the baking mold.

- Baking mold device: The baking mold is usually made of alloy cast iron, which has good high temperature resistance and uniform heating effect.

- Conveying device: It is chain-driven, and the baking molds are evenly distributed on the chain to achieve continuous production.

- Heating device: Usually natural gas or liquefied gas is used for heating, with high thermal efficiency and low energy consumption.

- Cooling device: Used to cool the freshly baked egg cone to prevent it from becoming soft

Advantages of Wafer Cone Production Line

- Customizable: Cones of different shapes, sizes and thicknesses can be customized according to customer needs. In addition to producing wafer cones, waffle cups, hollow wafers and other products can also be produced.

- High output: The machine can produce ice cream wafer cones in large quantities. Some production lines can produce 5,000-9,000 wafer cones per hour, or even up to 18,000, which can meet the needs of different customers.

- Durable: The main components of the production line, such as the top cover, burner barrel, casing, etc., are made of high-quality 201 stainless steel, and the parts in contact with food are made of 304 stainless steel, which meets hygiene and safety standards.

- Flexible: The production line adopts a modular design and can be expanded and upgraded according to needs. It can easily adapt to different production needs and support future product innovation.

Wafer Cone Production Line FAQ

- Q:How to choose the right machine for me?

- A: We will recommend the right machine model for you based on your finished product needs and output

- Q:What are the hygiene and safety standards of the production line?

- A: The production line is made of food-grade stainless steel, which meets food hygiene standards and ensures the safety and hygiene of the product

- Q:What is the service life of the production line?

- A: The production line uses heavy-duty rollers and special high-temperature grease to extend the service life of the equipment and reduce maintenance intervals

- Q:What is the after-sales service of the production line?

- A: We provide comprehensive after-sales service, including equipment installation guidance, operation training and after-sales maintenance.