Complete Sugar Cone Line Solution

Automatic Sugar Cone Production Line Durable & Efficient

Sugar cone production line is an automated equipment for mass production of ice cream cones, which is widely used in the food processing industry. The sugar cone production solution we provide is suitable for enterprises of all sizes, whether it is a small ice cream shop or a large food processing plant, you can find a solution that suits you.

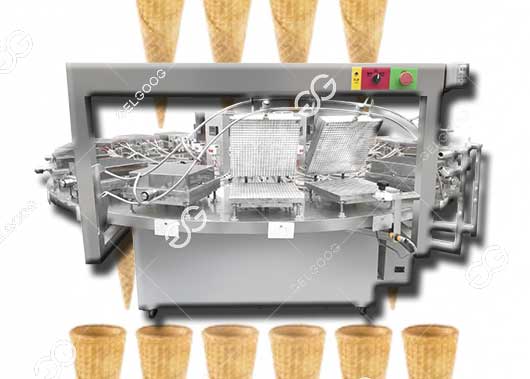

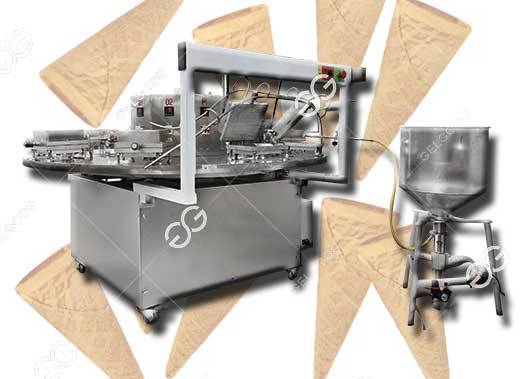

Sugar Cone Production Line

Product Features of Sugar Cone Production Line

- Highly automated: The sugar cone production line realizes the automation of the entire process from batter injection, baking, molding, cooling to packaging, reducing manual intervention and improving production efficiency.

- Diversified production: The production line can customize sugar cones of different shapes, sizes and flavors according to customer needs to meet diverse market needs.

- Efficient and energy-saving: Natural gas or liquefied gas is used for heating, with high thermal efficiency and low energy consumption.

- Sanitary and safe: The equipment is made of food-grade stainless steel, meets food hygiene standards, and ensures the safety and hygiene of the product.

- Easy to operate and maintain: Equipped with a friendly operation interface, the parameter setting is simple and intuitive, and the equipment structure is compact and easy to maintain

Process Flow of Sugar Cone Production Line

- Raw material mixing: Mix flour, sugar, water, oil and other raw materials in proportion to make a uniform batter.

- Batter injection: The batter is quantitatively injected into the baking mold through an automated injection system.

- Baking and forming: The baking mold is baked in a heating device to form the batter into a thin biscuit, which is then automatically rolled into the shape of a sugar cone.

- Cooling and conveying: The baked sugar cone is cooled on a conveyor belt to prevent it from softening.

- Packaging: The cooled sugar cone can be packaged manually or automatically.

Advantages of Sugar Cone Production Line

- Improve production efficiency: The automated production process enables continuous and stable production, avoiding pauses and instability in manual operation, thereby significantly improving production efficiency.

- Reduce waste: The automated injection system can accurately control the amount of batter used, reduce raw material waste, and improve the product yield.

- Diversified production: The production line can customize the shape, size, pattern and thickness of the sugar cone according to customer needs to meet the needs of different markets and customers.

- Fast switching: The production line design takes into account the production needs of different products, and can quickly switch to produce different types of products by adjusting the formula and process parameters.

- Strong durability: The use of high-quality materials and sturdy design reduces equipment wear and failure rate and extends the service life of the equipment.