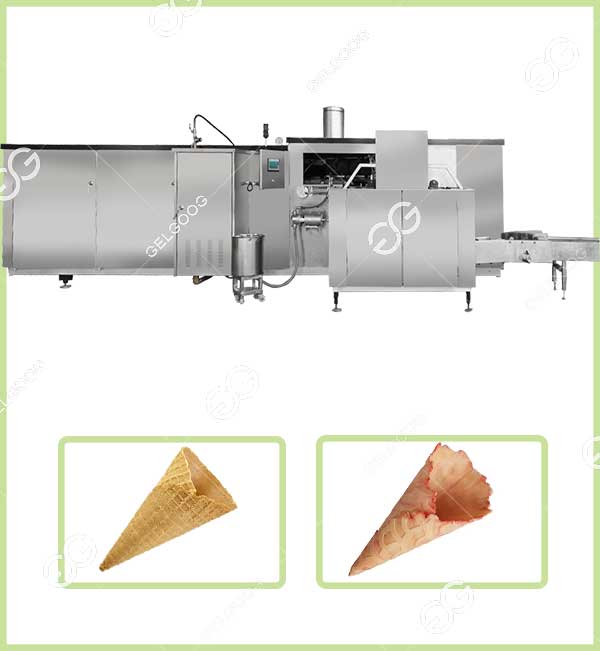

Features of Semi-Automatic Waffle Cone Making Machine

- Automation function: The batter is evenly injected into the baking tray through the grouting pump. Equipped with a temperature control system to ensure uniform temperature of the heating plate and consistent product quality. Some models are equipped with a PLC controller to automatically record the output.

- Diversified production: Supports waffle cones of various shapes and sizes, such as cones, bowls, sunflowers, etc. Customizable molds can meet the needs of different customers.

- Efficient production: The output of the semi-automatic waffle cone making machine is usually 500-1200 pieces/hour. Each heating plate can be controlled separately, and even if some heating plates have problems, other plates can continue to work.

- Easy operation: The equipment has a compact structure and simple operation, and usually only two people are needed to complete the operation. Detailed instructions and video tutorials are provided.

Semi-Automatic Waffle Cone Making Machine Operation Process

- Prepare the batter: Mix the raw materials according to the formula ratio and stir evenly to ensure that the batter is smooth and without lumps. Pour the stirred batter into the grouting bucket, which is connected to the grouting device of the machine through a pipe.

- Preheat the machine: Turn on the main power switch of the machine and ensure that all parts are well installed. Preheat the machine according to the manufacturer’s instructions. It is usually necessary to preheat the machine to the set temperature for about half an hour.

- Grouting: After the preheating is completed, turn on the grouting switch, and the batter is quantitatively sprayed onto the molds of each heating plate through the grouting device.

- Baking: The upper heating plate automatically falls and presses the batter into a pancake shape. The central intelligent temperature controller heats each baking box to quickly form waffles. As the heating turntable rotates for about one cycle, the waffle baking is completed.

- Forming: The upper heating plate automatically opens, and the baked waffle is manually taken out of the mold, quickly placed on the rolling machine, and rolled into a waffle cone shape. After rolling, the waffle cone is placed on the cooling rack to cool and shape.

- Cooling and packaging: The cooled waffle cones are packaged. Store the packaged waffle cones in a dry and cool place. Properly stored waffle cones can remain crispy for up to 6 months at room temperature.

Leave A Message To Get A Quote

Click to rate this post!

[Total: 0 Average: 0]

Reviews

There are no reviews yet.