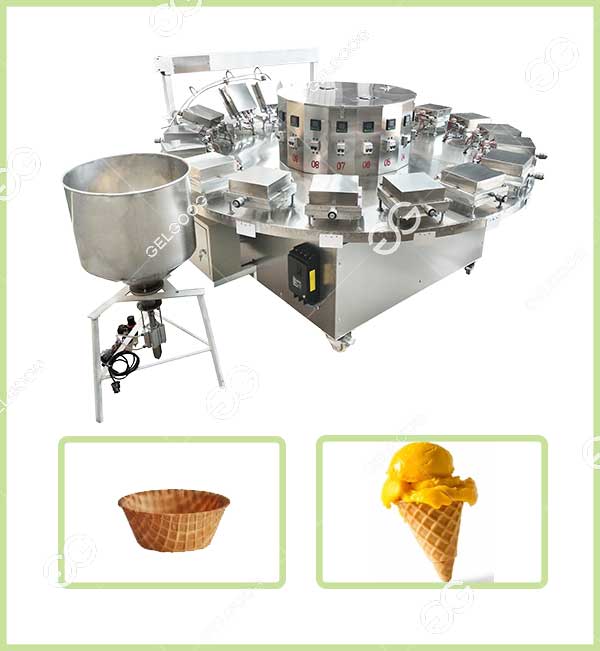

Industrial waffle cone machine is an automated equipment specially used for producing ice cream waffle cones. It combines multiple functions such as mixing, grouting, baking, cooling and packaging in one, and can efficiently produce waffles with soft texture and rich taste.

Industrial Soft Waffle Making Machine Process

- Raw material mixing: Mix low-gluten flour, sugar, eggs, milk, cooking oil, yeast and other raw materials according to the formula ratio.

- Stir evenly: Use a mixer to mix the raw materials evenly to form a smooth batter. The mixing time is usually 3-5 minutes

- Grooving system: The stirred batter is transported to the baking tray through the grouting pump. The grouting system is equipped with a rotor pump to ensure that the batter is evenly and quantitatively sprayed onto the baking tray

- Preheating the baking tray: The upper and lower heating plates of the baking tray are preheated to the set temperature, usually 160°C to 175°C.

- Baking process: The batter is heated in the baking tray to form soft waffles, and the baking time is generally 2.5 to 3 minutes.

- Temperature control: PLC control system is used to accurately control the temperature of the baking tray to ensure consistent product quality

- Cooling: After baking, it is cooled by the conveyor belt.

- Conveying: After cooling, it continues to move on the conveyor belt and is ready for the next operation

- Manual or mechanical forming: It can be rolled into a tube by hand or formed by a mechanical device as needed.

- Automatic packaging: After cooling, it is packaged by an automatic packaging machine. After packaging, it can be stored or sold directly.

Advantages of the Industrial Waffle Cone Machine We Sell

- Diversified products: Not only can traditional waffle cones be made, but also products of various shapes and flavors can be customized according to customer needs to meet the diverse needs of the market.

- Quick mold replacement: A separate batter pouring car is used to quickly replace the baking tray and roller to meet the production needs of different products.

- Precise control: The equipment is equipped with an advanced control system, which can accurately adjust the temperature, time and pressure according to different production needs to ensure the quality and taste of each waffle.

- Efficient energy utilization: Some equipment adopts optimized furnace design and energy-saving technology to reduce energy consumption. For example, the ventilated side door helps to reduce energy consumption and prevent the surface of the oven from heating up.

- Easy to clean: The baking tray and key components of the equipment can be quickly disassembled for easy cleaning and replacement, reducing downtime.

- Strong durability: The use of high-quality materials and advanced manufacturing processes ensures a long service life and low maintenance costs.

- Multiple application scenarios: Suitable for food processing companies, catering industry, home baking and other scenarios.

- Adapt to a variety of raw materials: Able to handle various types of batters and raw materials to meet different production needs.

Leave A Message To Get A Quote

Click to rate this post!

[Total: 0 Average: 0]

Reviews

There are no reviews yet.