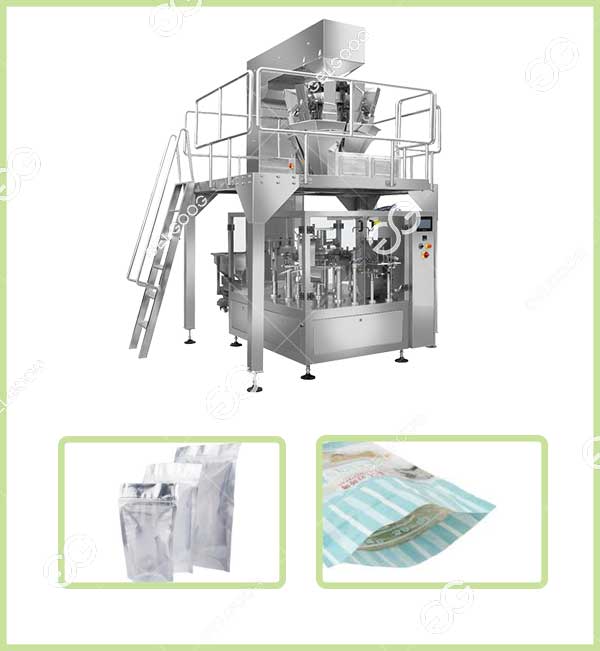

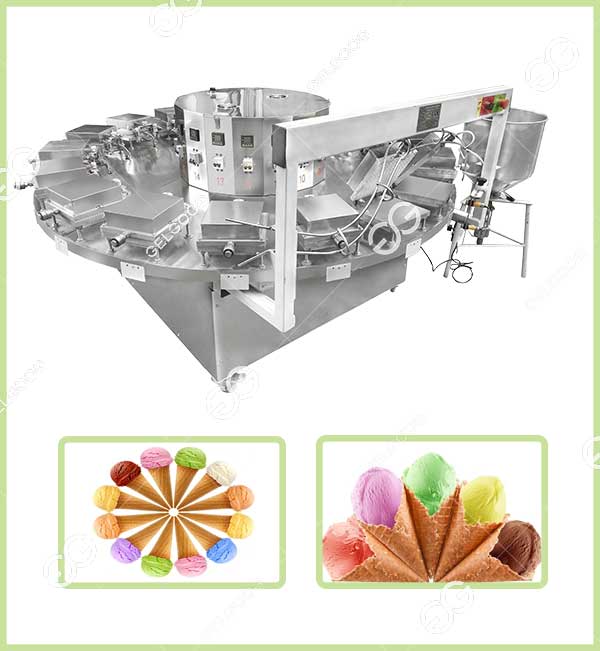

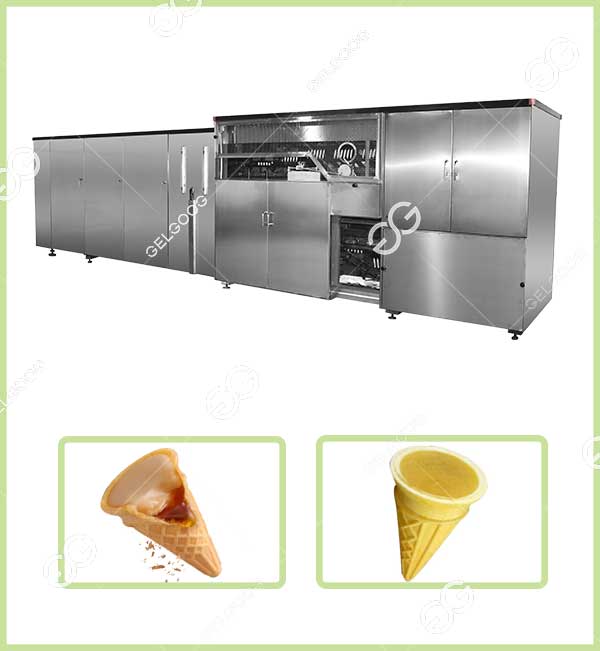

The multi-head weighing and packaging machine for ice cream cones is a high-precision quantitative packaging device specifically designed for ice cream cones. It combines an advanced multi-head computer-controlled combination scale with a high-speed vertical packaging machine to achieve accurate and efficient weighing and packaging of lightweight, fragile materials. It is perfectly suited for the automated production of ice cream toppings, yogurt toppings, and snack foods.

Technical Overview

High-Precision Multi-Head Computer-Controlled Combination Scale

- Utilizing a 10-14 head precision weighing system, the computer instantly calculates the optimal weight combination, overcoming the errors of traditional single scales. The weighing accuracy reaches ±0.5-1 gram, greatly reducing material waste.

Delicate Material Handling System

- Equipped with a specially designed scoop/tray type material cup and low-speed vibrating plate to ensure the material remains intact during conveying and weighing, reducing breakage rates, especially considering the fragile nature of ice cream cones.

Seamless Connection to Vertical Packaging Machine

- The combination scale connects directly to a high-performance vertical packaging machine, supporting various roll film materials for back-seal or four-side-seal packaging. It automatically completes a series of actions including bag making, filling, sealing, and coding.

Food-Grade Hygiene Standards

- All parts in contact with materials are made of SUS304 stainless steel and food-grade engineering plastics. The open structure facilitates quick cleaning and maintenance, eliminating unsanitary areas.

Why Our Combination Weighing Packaging Machine is an Industry Benchmark

- Measuring Accuracy and Cost Savings

The computerized combination weighing machine uses intelligent algorithms to achieve dynamic weighing compensation, fundamentally solving the problems of over- or under-weighing, directly saving you expensive egg cone raw materials. - Extremely High Production Efficiency

Multi-head simultaneous feeding and weighing eliminates the speed bottleneck of a single weigher. Packaging speeds can reach up to 60-80 packs/minute, easily matching your production line needs. - Superior Product Integrity

Gentle material handling ensures that fragile egg cone fragments remain in large particle form after packaging, improving product appearance and customer experience. - Simple Operation and Convenient Maintenance

The user interface allows employees to operate the machine after simple training. The modular design makes daily cleaning and parts replacement exceptionally simple.

Core Value for Your Business

- Significantly Reduced Raw Material Costs: High-precision metering means every gram of raw material is used effectively, eliminating waste.

- Improved Product Consistency: The weight and appearance of each package are highly uniform, strengthening brand reputation.

- Automated Production: Completely replaces manual weighing and filling, saving 5-8 workers and reducing reliance on manual labor and management costs.

- Ensuring Food Safety: Minimizes human contact, meeting modern food factory hygiene management standards.

Leave A Message To Get A Quote

Click to rate this post!

[Total: 0 Average: 0]

Reviews

There are no reviews yet.