Industrial Electric Waffle Cone Maker Process

- Raw material preparation: Mix flour, sugar, cooking oil, starch, baking soda and other raw materials in a certain proportion, and use a mixer to mix them into a uniform batter. Then pour the batter into the storage barrel for use.

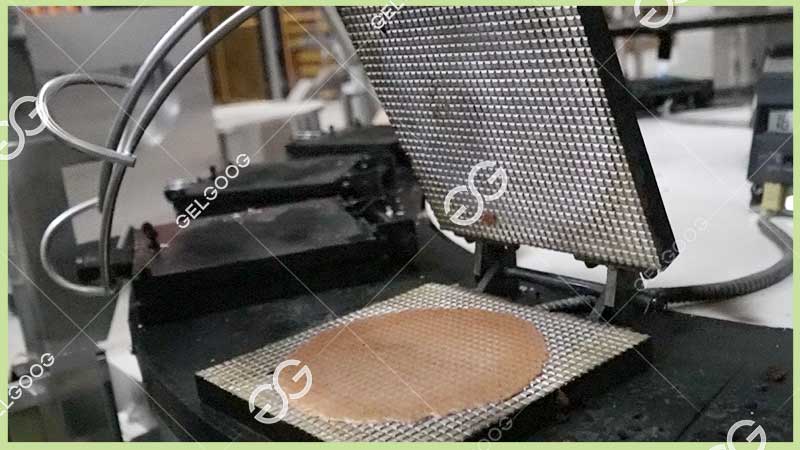

- Batter delivery: The batter in the storage barrel is delivered to the injection nozzle by a lifting pump, and the batter falls evenly on the baking tray in a quantitative manner. The baking tray is usually grid-shaped, and the batter falls on it to form a unique grid texture of the waffle cone.

- Baking: After the baking tray is closed, the batter is heated and baked in the baking tray, and it usually takes 5-10 seconds to form. The baking tray is heated by electric heating, which can ensure uniform heating and make the waffle cone golden in color and crispy in taste.

- Roller forming: The baked waffle cone sheets are fed into the roller forming machine, and the rotating roller device quickly rolls the cookie sheets into the shape of waffle cones. The size and shape of the roller can be customized as needed to produce waffle cones of different specifications.

- Cooling and conveying: The formed waffle cones are cooled and transported by the conveyor belt. The cooled waffle cones are more stable and convenient for subsequent packaging and storage.

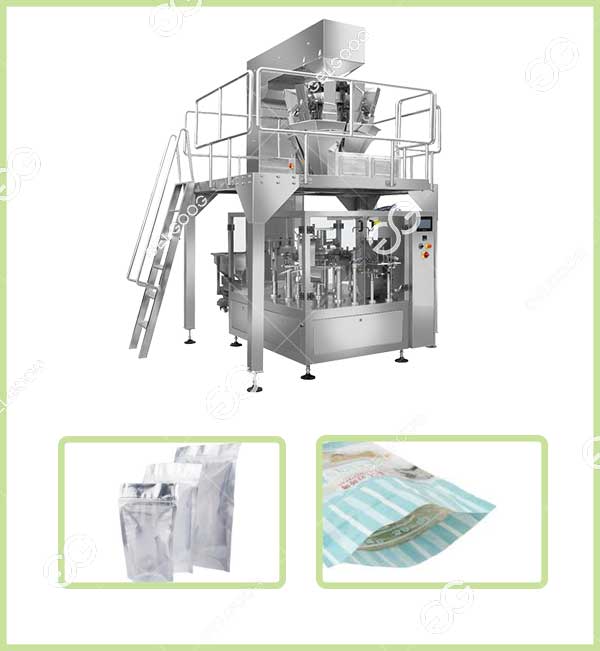

- Packaging and counting: The cooled waffle cones are conveyed to the packaging machine for automatic packaging and counting. The packaged waffle cones can be stored or sold directly.

Main Features of Electric Waffle Cone Maker

- Efficient production capacity: Industrial-grade waffle cone making machines usually have multiple independent operating stations, which can make multiple waffle cones at the same time, greatly improving production efficiency.

- Temperature and time control: Provides precise temperature adjustment function, the temperature range is usually between 50°C and 250°C, and users can make waffle cones with different tastes as needed.

- Durability and stability: Made of high-quality stainless steel, it has good durability and corrosion resistance, and the non-stick coating heating plate is easy to clean and has a long service life.

- Automation and safety: Equipped with automatic temperature recovery function, it can maintain a stable temperature during continuous production.

- The equipment usually has insulated non-slip handles and non-slip foot pads to prevent accidents during operation.

- Versatility: In addition to making waffle cones, some industrial-grade machines can also be used to make waffle bowls, egg rolls, pancakes and other foods

Leave A Message To Get A Quote

Click to rate this post!

[Total: 0 Average: 0]

Reviews

There are no reviews yet.