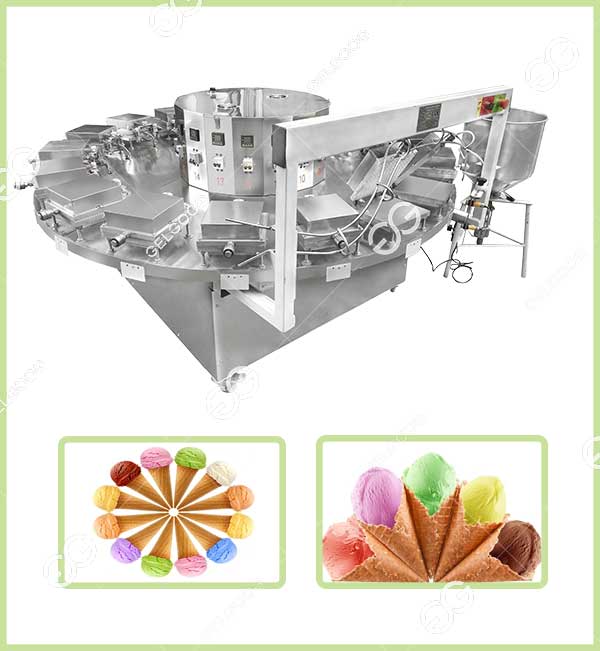

The industrial double ice cream cone machine is a device used for batch production of ice cream cones. It makes the batter into cones through a series of steps such as heating, molding, and cooling.

Features of the Industrial Double Ice Cream Cone Machine

- Reasonable structural design: It consists of a base and a top cover, and is formed into a whole with four columns. The first two columns also serve as guide columns. This design makes the machine stable as a whole and easy to operate.

- Flexible mold: The mold consists of an upper mold, a lower mold and a control frame. The mold can be replaced as needed to produce ice cream cones of different shapes and specifications.

- Centralized electrical control: The electronic control components are concentrated in the drawer under the frame. The screws can be pulled out as a whole after loosening, which is convenient for maintenance and repair.

- Easy operation: The cavity heating process is simple. The baking temperature is pre-adjusted by the temperature controller. The new machine generally sets the upper mold to 220℃ and the lower mold to 200℃. After heating to the set temperature, it can be tested.

- Efficient production: The double-head design enables the machine to produce more cones in a short time, improving production efficiency.

Working Principle of Industrial Double Ice Cream Cone Machine

- Raw material mixing: First, mix the flour, sugar, eggs, milk, butter and other raw materials in a certain proportion, stir evenly, and make a batter suitable for cone forming.

- Mold preheating: The double-head mold of the machine (usually two independent molding units) is heated by an electric heating element to reach the set temperature (generally between 150°C and 200°C).

- Batter injection: The batter is delivered to the mold. The amount of batter in each mold can be accurately controlled by the adjustment device to ensure that the thickness and size of the cone are consistent.

- Molding process: The batter is quickly solidified and formed after being heated in the mold. The molding time is generally 30 seconds to 1 minute, depending on the formula of the batter and the temperature of the mold.

- Demolding: The cooled cone is removed from the mold by a mechanical device, and the machine can ensure that the cone is completely and undamaged from the mold.

Industrial Desktop Double-Head Ice Cream Cone Machine FAQ

Q: What are the heating methods of the machine?

A: Double-head ice cream cone machines usually use electric heating, and the temperature can be set and adjusted.

Q: How to adjust the thickness and size of the cone?

A: By adjusting the distance between the upper and lower molds, ensure that the thickness of the cone is uniform.

Q: How to choose a suitable machine?

A: Choose the appropriate machine model according to production needs. If higher output is required, you can choose a fully automatic production line

Reviews

There are no reviews yet.