The global ice cream market continues to be hot. As the key container for carrying this sweetness, the quality of the cone directly affects the final experience of consumers.

What are ice cream cones made of? For large ice cream manufacturers, it is crucial to ensure the consistency, efficiency and hygiene standards of the cones. This is inseparable from the powerful industrial-grade cone production machinery.

Basic Raw Materials for Ice Cream Cones

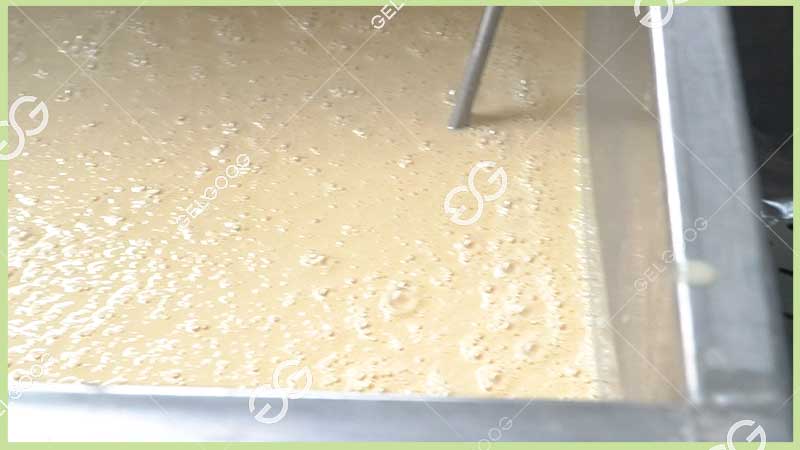

- Wheat flour: This is the main body of the cone structure, providing the necessary strength and crispy taste. Refined wheat flour is usually used.

- Water: Mix the dough to form a processable paste.

- Sugar: Not only provides sweetness, but more importantly, it promotes caramelization during baking, giving the cone its iconic golden color and unique caramel flavor.

- Vegetable oil/shortening: Increases the crispness and flavor level of the cone, and helps the dough not stick in the mold.

- Egg liquid/milk powder (optional): Sometimes added to enhance flavor, color (goldenness) and structural toughness.

- Salt: A small amount is used to balance sweetness and enhance the overall flavor.

- Understanding these basic ingredients is the starting point for optimizing the production process. However, turning raw materials into consistent quality cones requires cutting-edge industrial automation production lines.

- In response to the needs of large-scale food factories, modern cone production machinery has achieved full automation, high speed and precise control from raw materials to finished products.

- Designed for large-scale production, industrial-grade cone production lines can produce thousands or even tens of thousands of cones per hour, greatly meeting the supporting needs of large ice cream factories.

- The entire line is made of food-grade stainless steel and meets HACCP/GMP standards. Easy to clean and maintain thoroughly to ensure food safety. The solid structure ensures continuous and stable operation 24/7.

Why Choose an Industrial-Grade Cone Production Line?

- Economies of scale: Significantly reduce the production cost of a single cone.

- Consistency of quality: Precise machine control eliminates batch differences and ensures a uniform consumer experience.

- Improve efficiency: Automated processes significantly reduce manual dependence and speed up production cycles.

- Strict hygiene protection: Closed or easy-to-clean design minimizes the risk of contamination.

- Quick response to needs: Meet the high-speed filling needs of the main ice cream production line and seamlessly connect.

Understanding what is the cone of an ice cream made from is the foundation, and mastering the industrial technology to produce it efficiently, on a large scale and with high quality is the core of large ice cream manufacturers to maintain their competitiveness.

Are you ready to upgrade your cone production to industrial level? Contact our professional team now to get a customized cone production line solution to meet your ultimate pursuit of production capacity, efficiency and quality!