In the ice cream industry, the choice of cone significantly impacts product quality and customer experience. Two common cone types—sugar cones and waffle cones—are often confused, but they serve distinct purposes in commercial ice cream production.

Understanding their differences helps manufacturers select the appropriate equipment for optimal production.

Composition and Texture

- Sugar cones and waffle cones differ in their composition and structural properties. Sugar cones, with their higher sugar content, offer a crispy, firm texture that retains its shape well even in humid conditions.

- Their compact design makes them ideal for pre-filled applications, where storage stability is crucial.

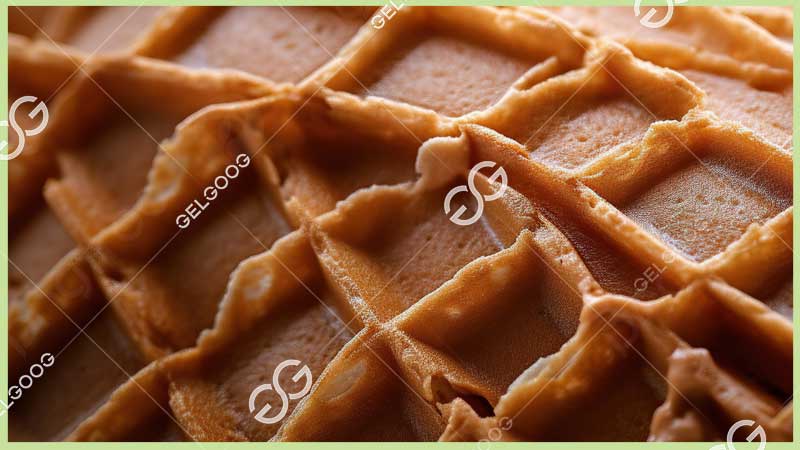

- Waffle cones utilize a lighter batter with a lower sugar content, resulting in a finer, fluffier texture. Their unique grid pattern is not only aesthetically pleasing but also increases surface area, accelerating heat transfer during baking and ensuring a uniformly crispy texture.

- This structure requires precise temperature control during manufacturing to prevent structural defects.

Production Requirements

Industrial cone production requires equipment that can maintain stringent parameters:

- Cone machines require a heavy-duty base to withstand the thick batter and precise temperature regulation to prevent caramelization before it properly sets. Our system achieves this through segmented heating zones that adjust in real time to changes in batter viscosity.

- Waffle cone equipment requires fast cycle times to accommodate thinner batters while maintaining crisp shapes.

- Our rotary design ensures uniform thickness across the entire surface, eliminating weak spots that can lead to breakage during filling or handling.

Choosing the Right Solution

When evaluating cone production equipment, consider the following factors:

- Product Portfolio – A dual-system installation allows switching between different cone types within a single shift.

- Footprint – Our modular design allows for capacity expansion without reconfiguring the production line.

- Hygiene – All contact surfaces meet EHEDG standards, reducing cleaning downtime.

For manufacturers requiring two cone types, our hybrid systems share common components, such as batter preparation and quality control stations, reducing capital expenditures while maintaining independently optimized baking processes.

The differences between cones and waffle cones extend beyond recipes and impact every aspect of industrial production, from equipment selection to packaging logistics. By tailoring machine specifications to the physical characteristics of each product, manufacturers can achieve superior yield and product integrity.

Please contact our engineering team to analyze your specific production needs.