In today’s competitive food industry, efficiency, hygiene, and product consistency are key factors in determining success, especially for manufacturers of cones, ice cream wafer cups, and traditional Italian pancakes. Manual or semi-automated production not only limits your capacity but can also lead to inconsistent product specifications and high labor costs.

It’s time to upgrade. Our High Efficiency Automatic Pizzelle Production Line is the ultimate solution.

Why choose a fully automated production line?

Before investing in new equipment, it’s important to understand the fundamental changes automation brings:

- Amazingly high throughput: Say goodbye to the slow pace of manual production. Our lines can operate 24/7, producing tens to hundreds of thousands of pieces per day, easily meeting large orders and growing market demand.

- Unparalleled consistency: Every pancake is perfect. Precise temperature control, batter metering systems, and consistent baking times ensure identical color, thickness, shape, and crispness from batch to batch.

- Dramatically reduced labor costs: Automated systems require virtually no human intervention. A single operator can monitor the entire line, freeing your staff to focus on more critical quality control and management tasks.

- Excellent Hygiene and Safety: The production line is constructed of food-grade stainless steel and complies with HACCP and ISO standards. The enclosed design and easy-to-clean surfaces significantly reduce the risk of food contamination and ensure product safety.

- Reduced Long-Term Operating Costs: While there is an initial investment, automated production delivers a higher long-term return on investment by reducing labor, minimizing material waste (through precise dosing), and improving equipment utilization.

Core Advantages of Our Production Line

Our High Efficiency Automatic Pizzelle Production Line is more than just a machine; it’s a complete production ecosystem.

- One-Stop Integrated Design: From automatic batter delivery, precise dosing, high-temperature baking, automatic forming (cones, bowls, flat wafers), to cooling and stack counting, the entire process flows seamlessly.

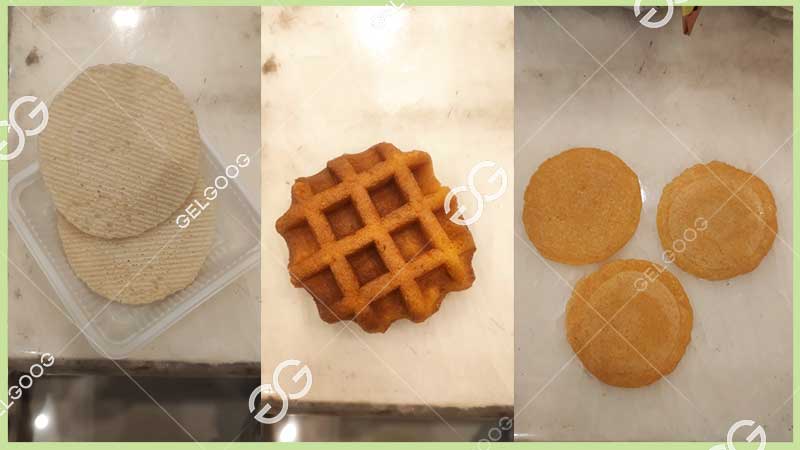

- Flexible Mold Changeover: The line supports quick mold changes, allowing you to easily produce cones, wafer cups, and flat wafers of varying sizes and patterns (such as traditional checkered patterns or custom logos).

- Intelligent Control System: A user-friendly PLC touchscreen interface allows you to precisely control baking temperature, time, and production speed. The recipe memory function makes product switching quick and easy.

- Energy-Saving and Environmentally Friendly: High-efficiency heating technology and heat preservation design significantly reduce energy consumption, saving costs for your business while also fulfilling your environmental responsibility.

- Durable: Core components are constructed from high-performance materials and precision-manufactured to ensure long-term, stable operation with minimal failure rates.

Choosing our fully automatic Italian cone production line is more than just purchasing a piece of equipment; it’s injecting a powerful growth engine into your business. You’ll gain:

- Consistent high quality to build a trusted brand reputation.

- Strong market competitiveness to stay ahead of competitors with superior cost and efficiency.

Are you ready?

We believe that the right equipment is half the battle. We not only provide world-class machines, but also comprehensive support services from installation and commissioning to operator training.

Contact us today for a personalized quote and detailed technical proposal! Let our professional team show you how to elevate your egg roll and wafer production business to new heights with efficient automation solutions.