Ice cream cones are a delightful dessert, but have you ever wondered how these crunchy, delicious cones are mass-produced in factories? Let’s take a closer look at the fascinating process behind the industrial-scale production of ice cream cones.

Raw Material Preparation and Mixing

- The production of ice cream cones begins with the preparation of raw materials. Typically, the raw materials include flour, sugar, water, oil, and sometimes eggs.

- These raw materials are carefully weighed and mixed in large industrial mixers to form a smooth batter. The batter is then transferred to a storage hopper and prepared for the next stage of production.

Baking and Forming

- The batter is pumped from the hopper into the baking machine and then distributed onto heated baking trays. The baking trays are equipped with conical molds that give the cones their unique shape.

- Once the batter is in place, the upper cover of the baking machine is closed and the batter is baked at a temperature of 180°C to 220°C for about 1-2 minutes. This process transforms the batter into crispy, golden brown flakes.

Rolling Into Cones

- After baking, the flakes are quickly transferred to the rolling device. Here, the hot sheet is rolled into a cone using a robotic arm or a special rolling head.

- The rolling process must be done while the sheet is still warm and pliable to ensure a perfect cone. The size and shape of the rolling head can be customized to produce different types of cones, such as waffle cones, cake cones, or sugar cones.

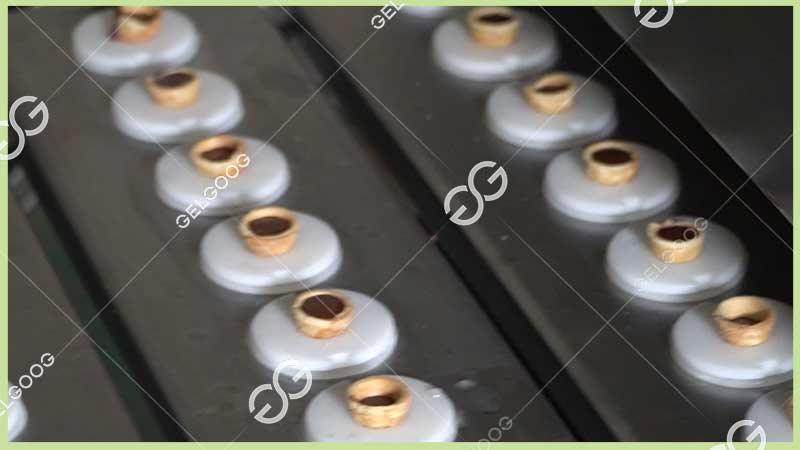

Cooling and Hardening

Freshly baked cones are soft and easily deformed. To keep their shape, the cones are moved to a cooling conveyor belt where cold air blows through them. The cooling process hardens the cones and ensures they remain crispy.

Packaging

Once the cones have cooled and passed quality inspections, they are ready for packaging. The cones are placed in paper sleeves or cartons, which not only protect the cones during transportation but also provide a good surface for branding.

Customization and Variations

Different types of ice cream cones have slightly different production processes. For example, the batter for waffle cones has a higher sugar content and is baked on a conveyor belt similar to a waffle iron. Cake cones, on the other hand, have a lower sugar content batter and are baked in upright molds. We offer customization options, such as adding branding or different flavors to the cone.

Factory ice cream cone production is a blend of precision engineering and culinary craftsmanship. Advanced machinery and automation systems ensure that each cone meets the highest quality standards, while efficient processes allow for large-scale production.

Whether you prefer a classic waffle cone or a crispy cake cone, the entire process from raw materials to finished product embodies the essence of modern manufacturing technology.

If you are interested in learning more about ice cream cone production equipment, or want to start your own cone making business, please consider contacting us for details and support.