When choosing equipment to produce ice cream cones, manufacturers must consider a core question: Should the cone be baked or fried? The answer depends on the type of cone and the desired texture.

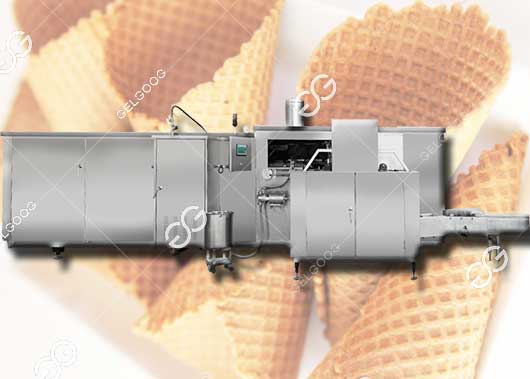

However, modern industrial production relies primarily on baking for efficiency, consistency, and quality. We design high-performance baking systems specifically tailored for cone production, ensuring precision, scalability, and superior product results.

The Science Behind Cone Production

Traditional homemade cones may be fried, but industrial production tends to bake for the following reasons:

- Even Heat Distribution – Our baking systems utilize advanced thermal engineering to ensure even heating, which is crucial for consistent color, crispness, and structural integrity.

- Oil-Free Process – Unlike frying, baking eliminates the need for excessive oil, reducing fat content and simplifying maintenance.

- Higher Production Speed – Precision-controlled ovens enable fast, continuous baking, which is essential for large-scale production without compromising quality.

Key Advantages of Our Baking Technology

Our industrial bakers are designed to meet the stringent requirements of cone manufacturers:

- Automated dough feeding and mold systems – Ensure precise thickness and shape, reducing waste. Adjustable temperature zones—optimize browning and moisture control for different cone types (waffle, sugar, or cake).

- Energy-efficient heating—reduces operating costs while maintaining high production output.

Why not fry?

While frying produces a crispy texture, it also presents challenges in an industrial environment:

- Unstable oil absorption—leading to inconsistent product quality.

- Higher maintenance costs—frequent oil filtration and changes are required.

- Limited scalability—difficulty achieving the same output rates as baking.

How Our Machines Streamline Production

- Precision Extrusion – A controlled pumping system delivers dough at a constant rate, eliminating manual handling variability.

- Uniform Mold Filling – An adjustable nozzle ensures uniform deposition, which is critical for maintaining the weight and thickness specifications of the cone.

- Non-Stick Coating – The molds are treated for easy release, preventing breakage and residue buildup.

- Robotic Extraction – An automated arm lifts the cone to the ideal cooling point, reducing manual handling and handling injuries.

- Quick Changeover – Modular molds and programmable settings enable quick switching between cone types (for example, from a waffle cone to a cake cone).

Conclusion

Modern ice cream cone production relies on baking for efficiency, uniformity, and a cleaner process. Our’s equipment is engineered to produce high-volume, precisely baked cones with minimal downtime and maximum return on investment.

For manufacturers seeking reliable, scalable solutions, our baking systems set the industry benchmark. Contact us to learn how our technology can optimize your production line.