Designed for high-volume production environments, our industrial-grade fully automatic ice cream cone filler integrates advanced technologies to simplify the filling process, making it precise and efficient.

Technical Parameters

- Production capacity: 60-120 cones per minute, adjustable according to cone size and filling volume requirements.

- Filling accuracy: ±1% of set capacity, ensuring consistent product weight for each cone.

- Cone compatibility: Applicable cone diameter range is 30mm to 60mm, height range is 60mm to 120mm, and custom parts are available for special sizes.

- Power supply: 380V/50Hz, three-phase, total power consumption 4.5kW.

Core performance advantages

- Precision filling system: Equipped with a servo-driven plunger pump, the filling volume is accurate and there is no dripping or overflow. The pump is easily disassembled for cleaning, reducing downtime between production batches.

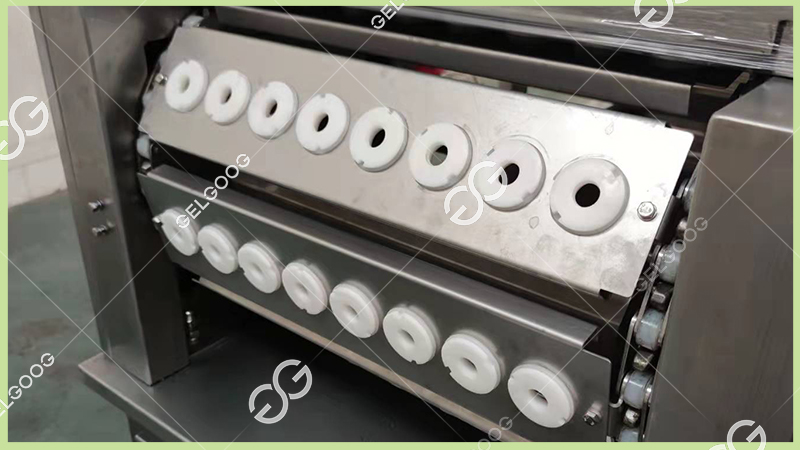

- Automatic cone conveying: Mechanical feed mechanism with sensor detection ensures reliable cone positioning. The cone is smoothly conveyed by an adjustable speed conveyor belt, synchronized with the filling process to avoid blockages.

- PLC Control System: Operators can set parameters such as filling volume, production speed and conveyor speed through a touch screen interface. The system can store up to 50 production recipes, allowing for quick switching between different products.

- Hygienic Design: All food contact parts are made of food-grade materials with smooth surfaces to prevent residue accumulation. They can be thoroughly cleaned with water and detergent.

- Stability and Durability: The frame is welded from thickened steel plates to minimize vibration during operation. Key components such as bearings and motors are sourced from reputable manufacturers to ensure long-term reliability.

Operational Efficiency

- Quick Changeover: Tool-free adjustment of filling nozzles and cone guides allows for rapid switching between different cone sizes and filling specifications, reducing changeover time to less than 15 minutes.

- Low Maintenance Requirements: Self-lubricating bearings and sealed drive systems reduce the need for frequent maintenance. The machine is designed with accessible components, making routine inspections and repairs straightforward.

- Energy Efficiency: The servo-driven system adjusts power output based on production demand, reducing energy consumption during low-speed operation.

Application Scenarios

Applicable to large ice cream production facilities, including plants that produce packaged ice cream cones for the retail, catering and food service industries. Suitable for a variety of ice cream recipes, including soft ice cream, hard ice cream, and high-end ice cream with added ingredients such as chocolate chips or nuts, with appropriate pre-treatment.

The ice cream cone filling machine is designed to meet the stringent requirements of industrial production, focusing on precision, efficiency and compliance with food safety regulations to support consistent product quality and high output.