Modern egg roll production lines, with their sophisticated mechanical design and intelligent control systems, completely address this pain point.

Traditional handmade egg rolls rely heavily on the operator’s experience and proficiency, inevitably leading to variations in size, thickness, and crispness.

Modern Egg Roll Production Lines

- Precise Temperature Control and Baking: The production line utilizes a constant temperature control system to ensure uniform temperature across every area of the baking pan.

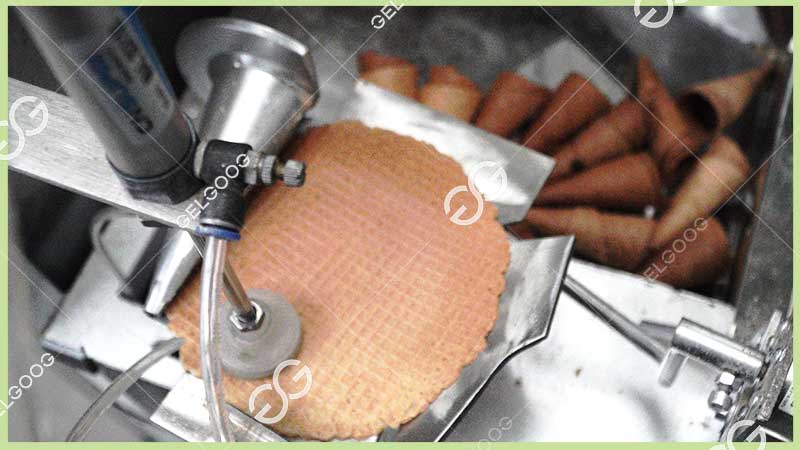

- Automated Roll Forming: The core rolling process is performed by a high-precision robotic arm or roller mechanism.

- Consistency Guarantee: From batter to finished product, the entire process is automated, minimizing human interference and ensuring that every egg roll produced in batches is of identical quality.

Advantages of Our Machines

For companies aiming to expand production and meet market demand, production efficiency is paramount.

- Continuous Operation: The production line seamlessly integrates battering, baking, rolling, cutting, and conveying processes into a smooth, continuous flow. This significantly shortens production cycles and exponentially increases production capacity compared to traditional methods.

- Optimizing Labor Costs: Automated equipment replaces a significant amount of repetitive manual labor, significantly reducing reliance on skilled workers, effectively saving labor costs, and enabling companies to invest their human resources in more critical roles such as quality control, R&D, and management.

- 24-Hour Non-Stop Production: Stable and reliable equipment performance supports long-term, even around-the-clock, operation, helping companies quickly respond to large orders, seize market opportunities, and enhance their competitiveness.

Balancing Food Safety and Flexible Production

The modern food industry has increasingly stringent requirements for both safety and flexibility, and advanced egg roll production lines provide strong support for this.

- High Standards of Hygiene and Safety: Equipment is typically constructed of stainless steel that meets food hygiene standards, and its design is easy to clean and maintain. A fully enclosed or semi-enclosed production environment minimizes human contact, fundamentally reducing food safety risks.

- Flexible Recipe Adaptability: An excellent egg roll production line offers excellent production flexibility. By adjusting equipment parameters, different recipes (such as whole egg rolls, sesame egg rolls, and vegetable egg rolls) can be easily adapted to meet diverse consumer needs.

- Data-Driven and Intelligent: The integrated PLC and touchscreen human-machine interface make operation intuitive and simple. Production data can be recorded and analyzed, providing data support for process optimization and lean production.

We are committed to providing global food companies with comprehensive egg roll production solutions that deliver cutting-edge technology and stable performance. Our team of engineers will tailor the most suitable production line to your specific needs, helping you stand out in the fiercely competitive market and create a bright future for the egg roll industry.