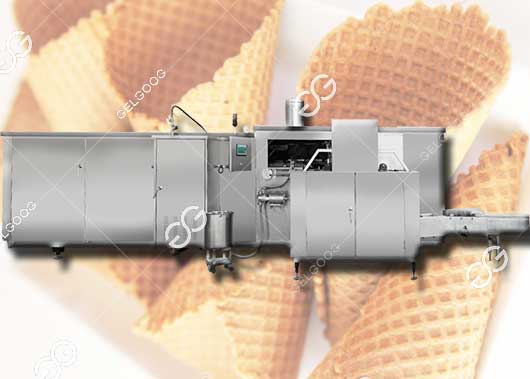

Automatic Ice Cream Cone Line Solution

Automatic Ice Cream Cone Line Solution For Sale

Ice cream cone production line is an automated equipment for mass production of ice cream cones, which is widely used in ice cream factories and food processing enterprises. It can provide users with efficient, stable, safe and economical production solutions to meet the needs of ice cream production enterprises of different sizes and needs.

Ice Cream Cone Production Line

Main Components of Ice Cream Cone Production Line

Batter preparation system: used to mix flour, sugar, water, oil and other raw materials in proportion to make a uniform batter.

Injection system: The injection head moves synchronously with the baking mold, and the batter can be quantitatively injected into the baking mold.

Baking mold device: The baking mold is made of alloy cast iron, which is resistant to high temperature and heated evenly, and can be customized in different shapes and sizes.

Conveying device: It is chain-driven, and the baking molds are evenly distributed on the chain to achieve continuous production.

Heating device: It is usually heated by natural gas or liquefied gas, with high thermal efficiency and low cost.

Cooling device: It is used to cool the freshly baked egg rolls to prevent them from becoming soft.

Packaging device: Some production lines are equipped with automatic packaging machines, which can be customized according to needs

Workflow of Ice Cream Cone Production Line

- Batter preparation: The automatic stirring system mixes the raw materials into a uniform batter.

- Batter injection: The injection system injects the batter into the baking mold in a quantitative manner.

- Baking: The baking mold is baked in a heating device to form the batter into thin biscuits.

- Egg roll forming: The baked biscuits are automatically rolled into egg roll shapes.

- Cooling and conveying: The egg rolls are cooled on the conveyor belt and then automatically arranged and discharged.

- Packaging: The cooled egg rolls are collected and packaged by workers.

Features of Ice Cream Cone Production Line

- Highly automated: The automated control system ensures the stability and consistency of the production process. The entire production process requires almost no human intervention, which improves product quality and production efficiency.

- Diversified production: The production line can be customized according to customer needs, and can be customized in different shapes, sizes and flavors. It can flexibly add new functional modules or upgrade existing equipment.

- Energy-saving and efficient: Natural gas or liquefied gas is used for heating, with high thermal efficiency, fast heating speed and low energy consumption. The equipment is equipped with heat insulation cotton to reduce heat loss and further reduce energy consumption.

- Sanitary and safe: The entire production line is made of food-grade stainless steel, which meets food hygiene standards and ensures the safety and hygiene of the product.